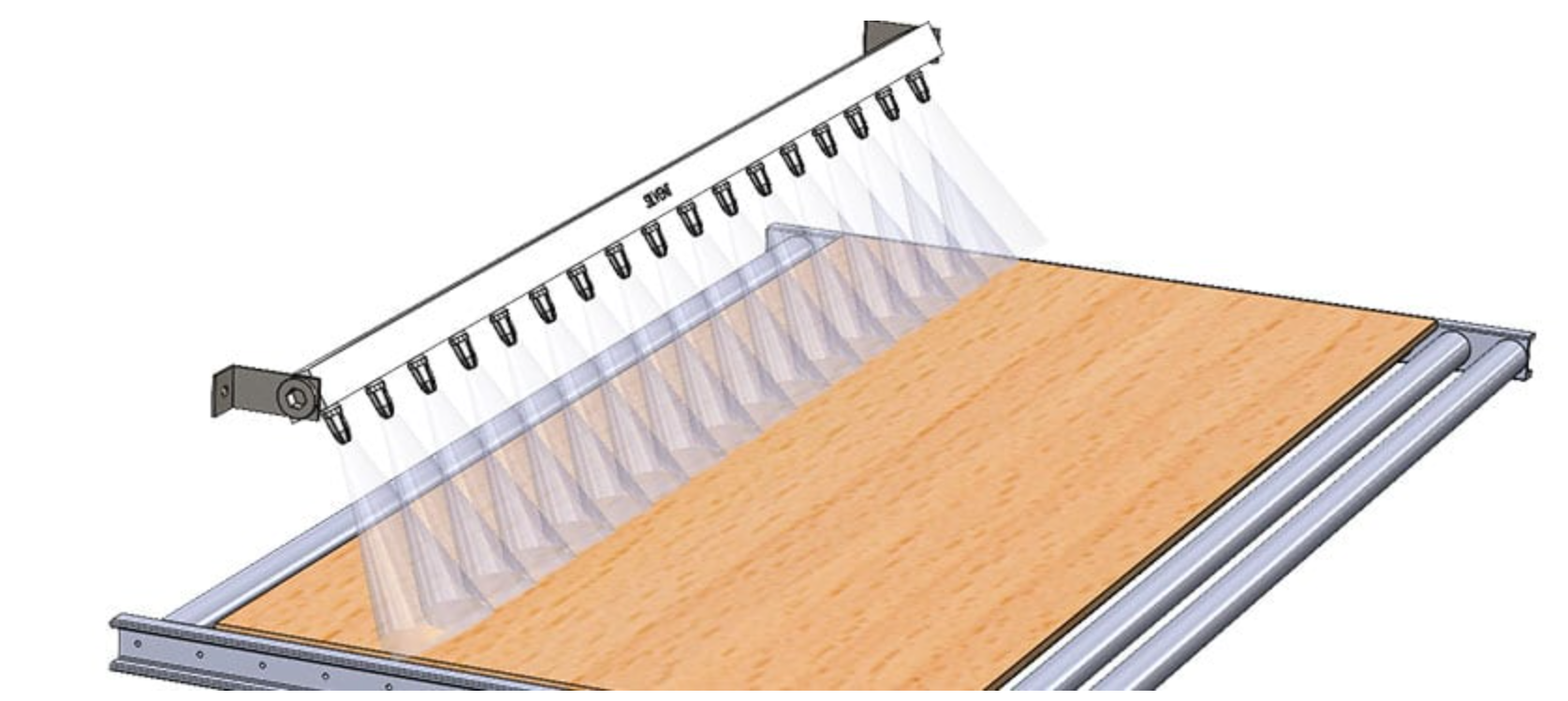

In order to achieve good results when painting MDF, the surface must be completely free of sawdust and dirt. The company's existing solution applied their own air knife and nozzle design, but lacked the knowledge of how to make the air blades more efficient to use. As a result, there were still many problems with the existing solution, such as high decibel noise levels that violated the company's regulations, so the company was actively working to reduce noise levels in their production.

Customized air knives are designed by Bevane engineers, who draw on a wealth of experience and expertise to deliver efficient compressed air blowdown. In order to minimize sound levels, the blowing force, blowing method, blowing distance and blowing angle need to be adjusted to suit their unique application. Tests carried out before and after the installation showed a 10 dB reduction in noise levels, halving the noise to the human ear, and a 25% energy saving for the unit.